[ad_1]

The past two years of the global pandemic revealed some interesting trends, but one stands out: lockdowns, restrictions and overall sense of impending doom did not curb consumption. ANGELA HAN explores some of the anticipated changes to the supply chain in this brave new world.

Throughout history, global disasters elicited one response – practice austerity to prepare for adversity. Potatoes were planted and belts tightened as individual priorities shifted from spending to saving.

Supply chains ground to a halt, but that’s because consumption also slowed, and people only opened their wallets for absolute necessities.

However, this 21st century crisis impacted differently. While cities and streets emptied overnight with restrictive lockdowns,

the internet teemed with traffic. From streaming a new Netflix series to buying milk or an engagement ring, our collective consumption didn’t stop – it was simply redirected. And it flourished.

Highway car crashes were replaced with server crashes – additional tech resources had to be bolstered as ecommerce went into hyperdrive, and people discovered the convenience of home delivery. Couriers took over the empty streets to deliver fast food, fast furniture and fast fashion.

Indeed, the total retail sales from the US Commerce Department data showed a growth rate of 14.0 per cent (an all-time high) in 2021 — and Australia’s 2020 annual retail figures increased by 6.17 per cent to $349.9 billion from $329.56 billion in 2019, pre-COVID.

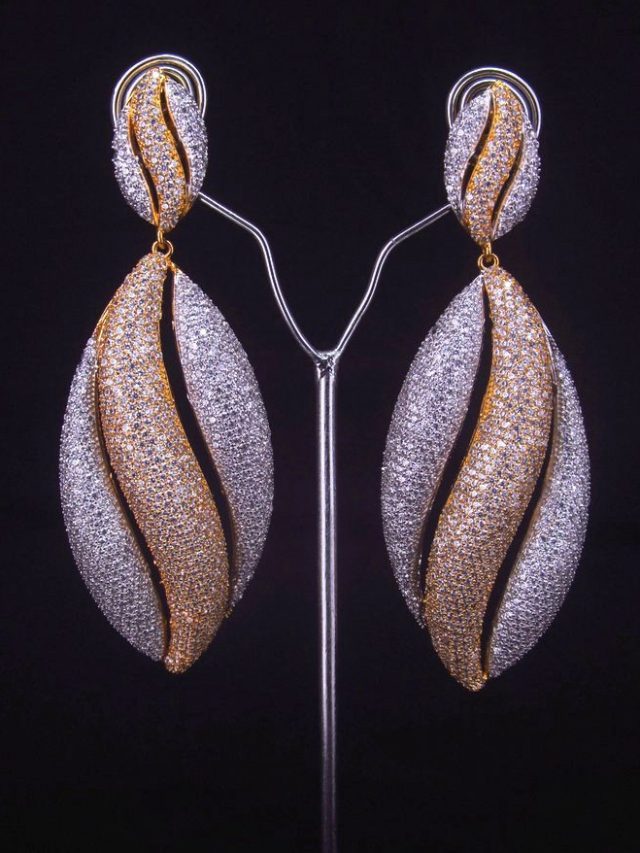

Jeweller reported a 4.8 per cent increase in jewellery sales this past December. We also saw retail trading figures being buoyed by luxury consumption throughout the pandemic. The watch and jewellery sector evidently experienced momentous growth – from the rising share prices of large conglomerates such as LVMH and Chow Tai Fook, to local jewellers of all sizes reporting record sales; these trying times brought surprising outcomes.

Times have changed – this is a far cry from potatoes and tighter belts!

But while consumption was up, supply chains took a hit. In the Insta-age where everyone wants everything yesterday, the global supply chain is poised for permanent change.

Enlightenment through crisis

The pandemic exposed critical supply chain risks that exist in the vast globalised network from which have been benefiting for decades.

Indeed, with the recent rise of geopolitical conflict, sanctions, inflation and freight costs, combined with the complexities of the pandemic, businesses have had to quickly embrace new operational procedures to remain competitive.

The affordable logistics we’ve grown to depend on for our deliveries will no longer be a ‘given’, especially as delivery demand and consumption is set to increase, forcing manufacturers to move production closer to customers who are looking for a more ‘local’ solution.

For example, international shipping costs for a 40-foot container increased on average from US$1,331 at the end of February 2020, to US$11,109 by mid- September 2021. Coupled with worldwide labour shortages, the problems plaguing the supply chain was highlighted initially through failing logistics.

Moreover, restrictive trade policies became a roadblock for many businesses that relied on imports, which forced companies to reassess how much of their business relied on overseas operations.

Enter stage right: traditional brick-and- mortar stores. Consumers that had been habituated into purchasing online found that prices were no longer competitive after increased freight costs and the inconvenience of unreliable delivery time. It was quicker to drive down to the local shopping centre and gain immediate access to the same item for less.

The consumer’s focus is no longer about getting the cheapest item but rather on the quality and speed of delivery where they can happily hand over money to someone they trust.

Recognising that supply chains will not return to the same way before COVID is critical to moving forward. For example, logistics companies are experiencing higher costs and salaries from the tight labour market. In response to these changes, businesses need to consider carrying additional essential inventory and diversify their supply chains by sourcing from alternative manufacturers that are closer to their own consumer base.

In the short-term, business costs are anticipated to increase as we navigate the long-term changes in the supply chain. Good groundwork today will cost businesses less tomorrow.

Looking for solutions closer to home looks to be a good starting point, because for now it looks like consumers prefer to ‘pop to the shops’ than ‘hop online’.

A Yin and Yang solution

The big question for 2022 is: how is COVID-19 is going to continue to affect supply chains, and what are the solutions? Well, like everything in life, it’s a matter of finding a perfect balance.

Businesses have become acutely aware of their interdependent reliance on overseas suppliers to supply critical components

of finished products. While global supply chains will continue to exist, there will be a lot more pressure for local involvement and content in products.

For example, with the ongoing trade wars, many companies have had to adopt a ‘China plus one’ strategy.

It’s a fact that China remains a manufacturing giant, and thus this approach is adopted by businesses wanting to slowly reduce their reliance on Chinese manufacturing without cutting the country out completely. All the while they continue to ‘balance’ their investment across other regions such as India, Indonesia, Thailand and Vietnam, and may also diversify into local manufacturing options.

However, given the cost of local labour, manufacturers and distributors will need to increasingly rely on automated processes involving technology such as blockchain and artificial intelligence.

As tech bolsters productivity for evolving supply chains, it also demands a skilled workforce and investment into new technologies to truly harness the benefits. Low-cost labour will be replaced with high-skilled labour to help manage businesses efficiently.

The old is gone, and the new has come – tired cheap manufacturing and traditional supply chains are over. To remain ahead of the problem, businesses need to reevaluate their workforce; if low-cost labour is the only solution to the supply chain problem, the future looks bleak. A skilled workforce and business leaders who know how to cultivate talent is essential to tackling the issues ahead.

After all, humans drive technology and innovation – not the other way around.

[ad_2]

Source link